Rubber MEGAPAINT

Overview

Rubber MEGAPAINT

Megadyne has developed RPP8 and RPP 14M timing belts designed for conveyor and transfer lines, specifically for painting systems: the MEGAPAINT belt.

MEGAPAINT belts are silicone free and do not contain contaminants, as requested for water or solvent based paints; the purity of materials and the absence of polluting particles always guarantees perfectly painted surfaces and without any defect.

Features

Rubber MEGAPAINT is silicone free and without surface impurities and contaminants, according to car manufacturers’ standard.

Test performed by the Forschungsinstitut für Pigmente und Lacke e.V. of the Stuttgart University.

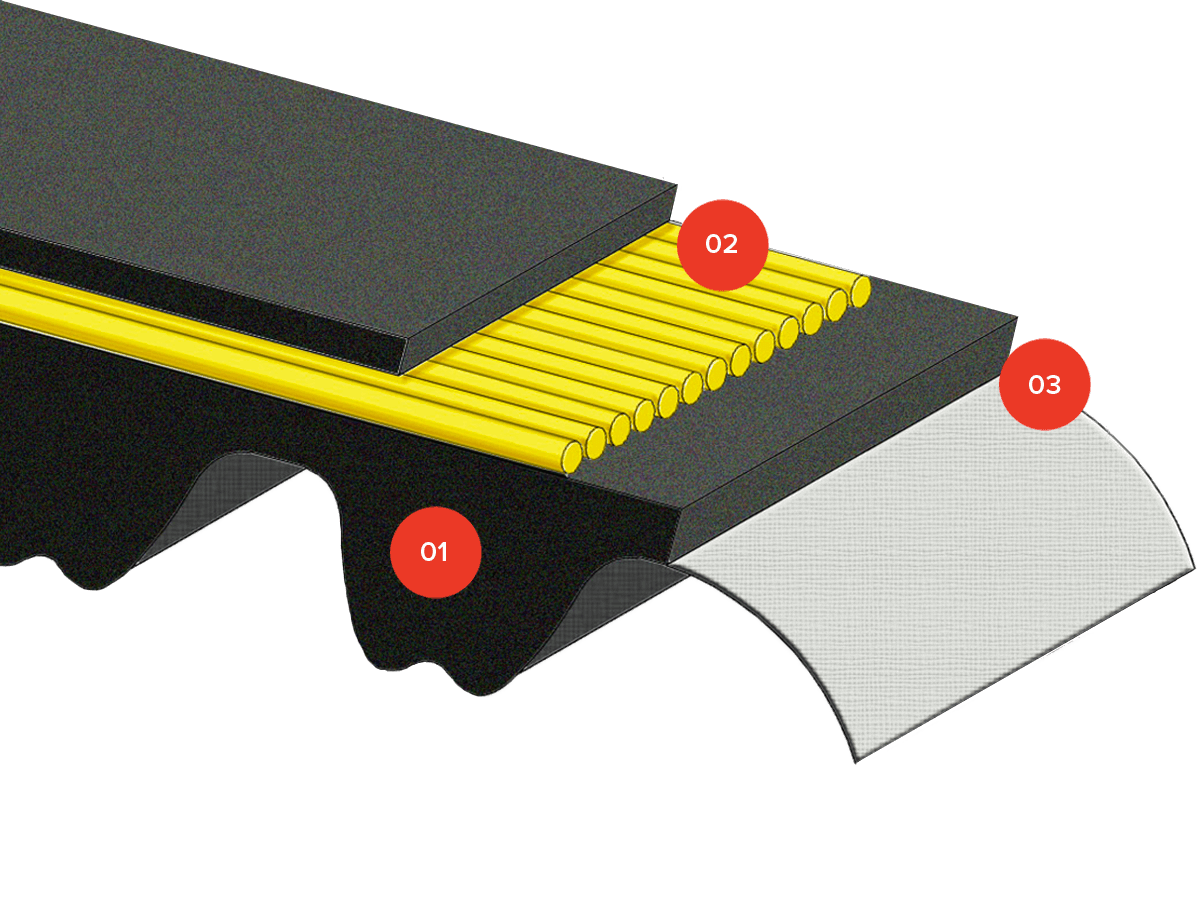

Main components

01 / BODY

Belt body and back made of NBR based compound with a high purity degree and without contaminating agents.

02 / CORD

Fiberglass cords with high elastic module and a special surface treatment.

03 / FABRIC

Fabric on teeth with high wear resistance, with a nitrile based treatment to protect the external surface

Mechanical and chemical properties

- Silicone free

- High resistance to ozone and adequate resistance to lubricating oils

- No need at all for maintenance and lubrication

- Rubber MEGAPAINT belt working temperature -20°C/+100°C